FLARE™

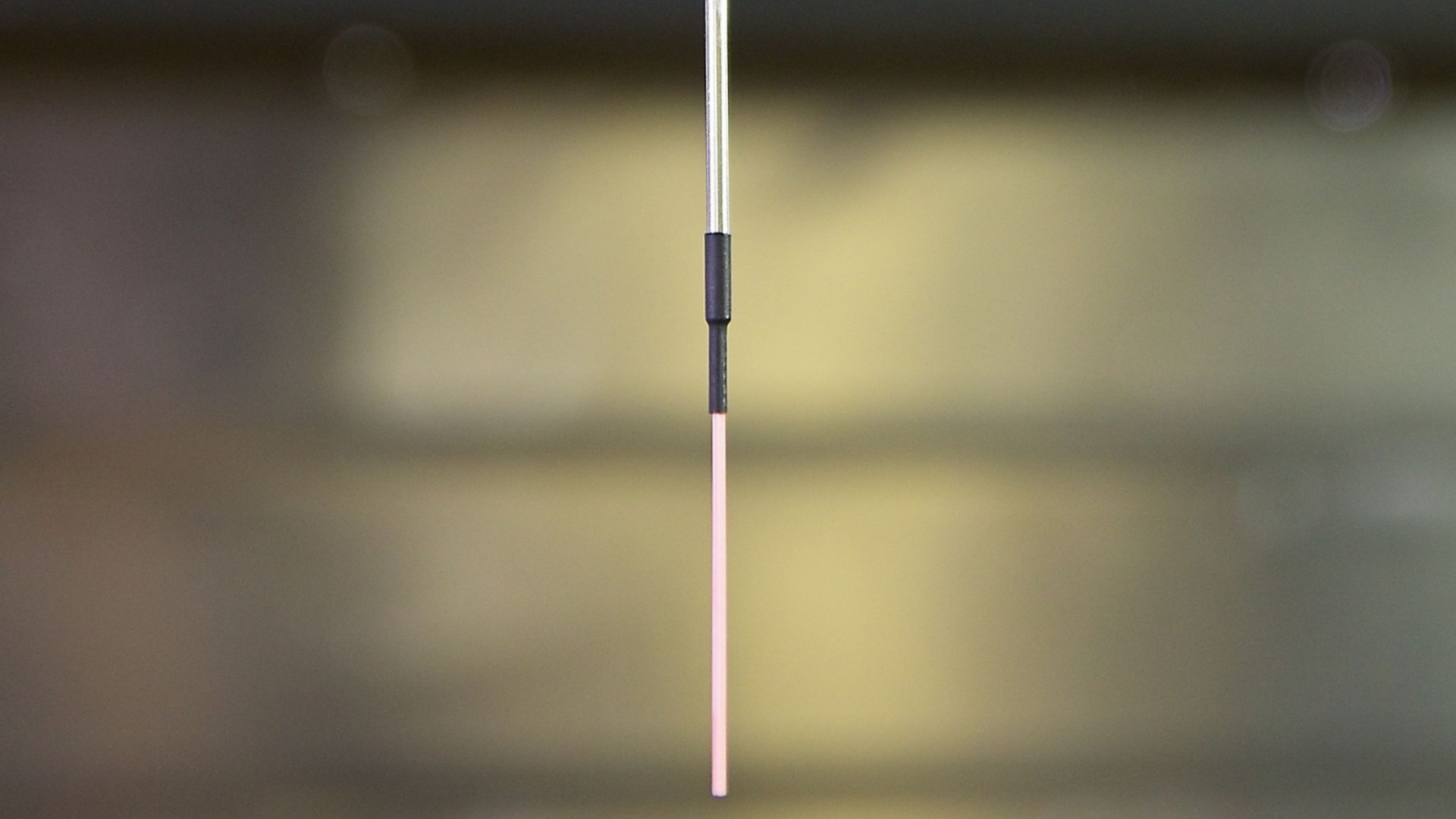

ESS Flare™

Extended Lenth Deburring Brushes for CNC Machines

The ESS Flare™ line of Cross-section deburring brushes is engineered specifically for high-precision internal bore and intersecting-hole burr removal and polishing applications. These tools are ideal when you need controlled edge-blend and burr elimination in cross-secion, ports, valve bores, and tight-tolerance interior passages—with minimal impact on the surrounding geometry.

Why Flare™

- Delivers clean, burr-free ports and cross-sectionwithout altering bore size or shape

- Enables automated, repeatable finishing with minimal operator intervention

- Reduces secondary hand-deburring operations and improves part throughput

- Maintains tight tolerances and surface integrity, avoiding post-process inspection issues

Process Guidelines

- Secure the tool in a spindle or toolholder; ensure proper collet grip and tool balance.

- Extend the brush into the bore until fully inside; engage at programmed speed while ensuring steady contact.

- Use reciprocating or helical motion across the deep-hole intersection for uniform burr removal and surface refinement.

- Typical recommended speeds range from 6 000 rpm to 12 000 rpm depending on diameter and material. Feed selections may range 200 mm to 1 000 mm per minute in automated setups.

- Coolant, air purge, or mist lubrication is advised to manage heat and keep debris cleared for optimal finish.

ESS Flare™ brushes are the advanced choice when you face the challenge of deburring deep hole and intersecting passages in precision components. With ceramic-fiber filament construction, customizable geometry, and high durability, Flare enables burr removal, edge-blend and finished bore polishing—all while preserving critical dimensions and geometry integrity.

Features & Applications

Looking for more? Browse the catalog

Download and browse the entire catalog, click below for our geometric offering.